10 Construction Site Operations Powered by SpatialSense

10 Construction Site Operations Powered by SpatialSense

This blog highlights 10 key construction site operations, the challenges they encounter, and how a platform like SpatialSense can streamline, monitor, and optimize them.

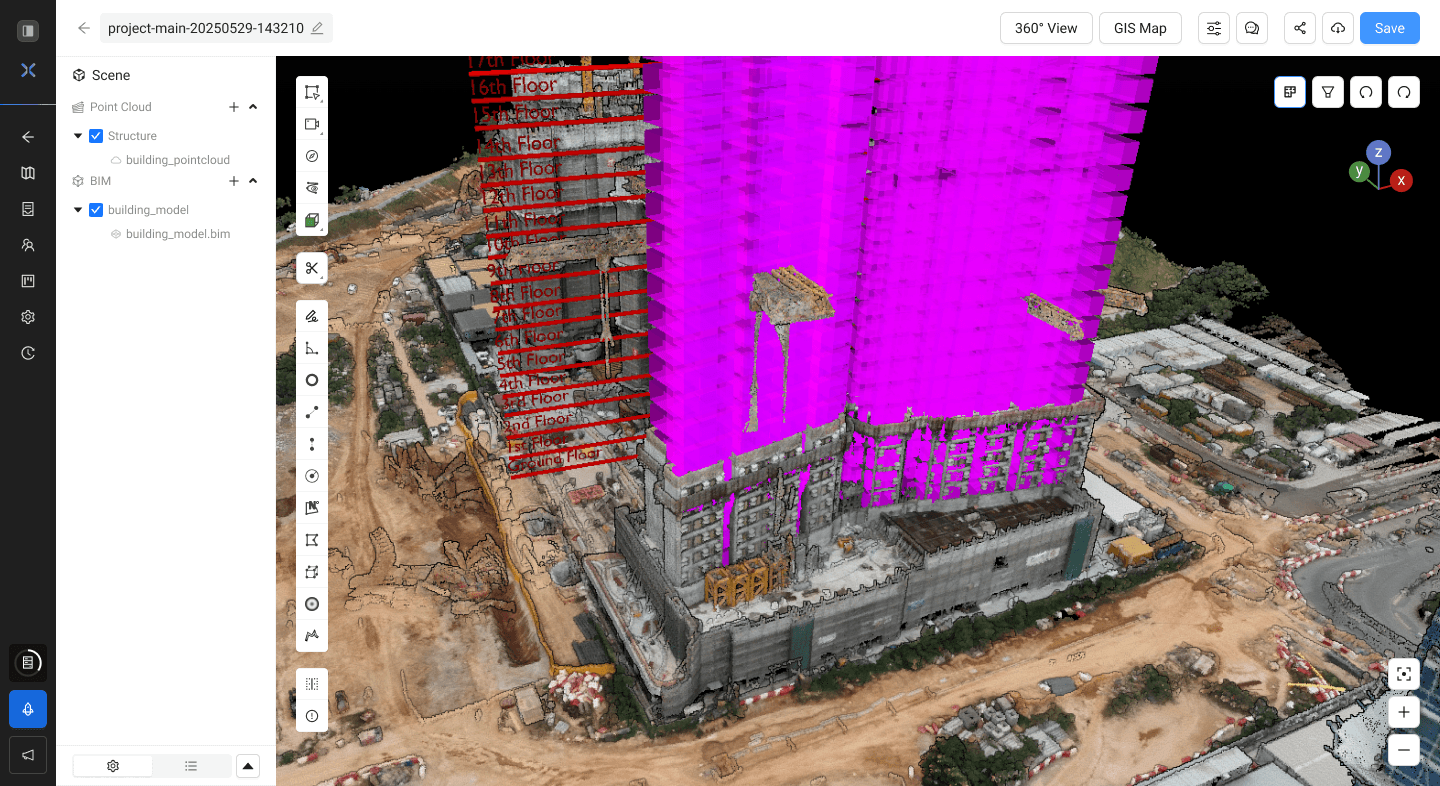

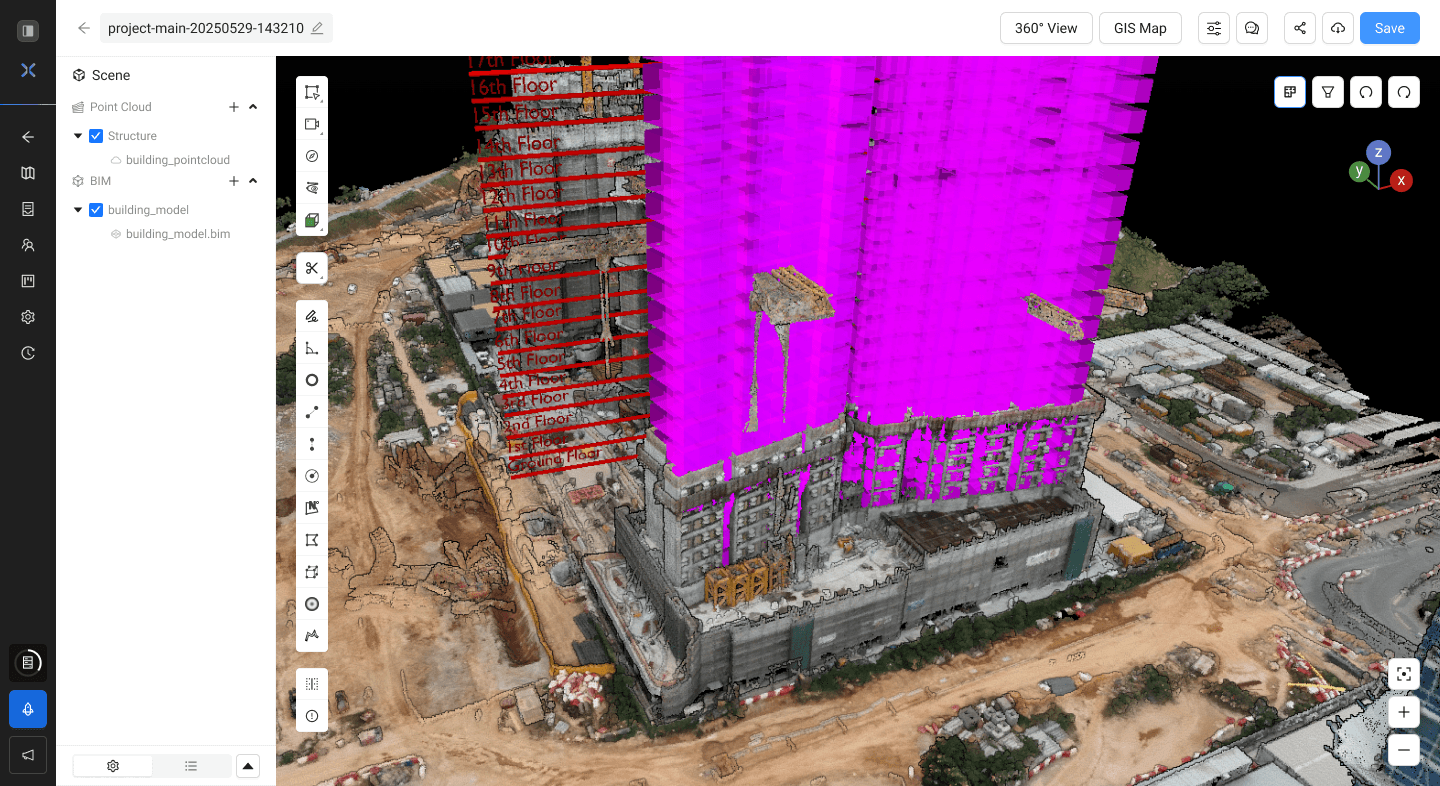

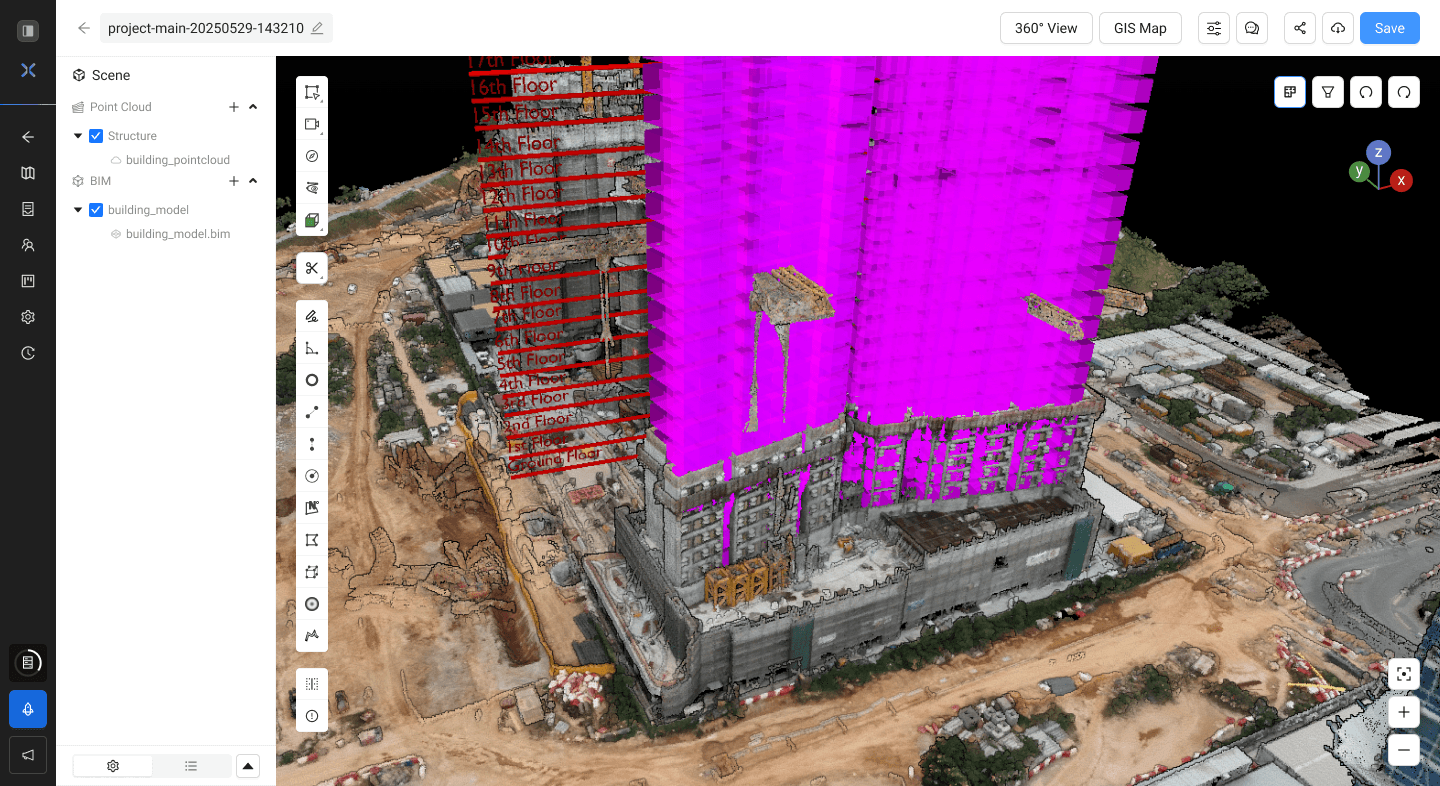

1. Modular Integrated Construction (MiC) Progress Monitoring

Modular construction accelerates projects but can be difficult to manage due to complex logistics, limited visibility and having multiple stakeholders - leading to misaligned schedules or missing components.

A Platform like SpatialSense compares point-cloud captures with the BIM schedules (4D BIM), monitoring delivery, on-site assembly, and installation of modular components. AI detects completed, in-progress, and missing modules, while dashboards provide real-time progress percentages with various other analytics.

Enabling on-time, on-budget delivery, reduces dependency on manual reporting, and improves visibility for onsite activities.

2. Tower Crane & other Machinery Utilization

Tower cranes and other construction equipment are expensive and critical for operations, but traditional utilization is often tracked manually, causing inefficiencies and idle time.

SpatialSense’s AI-powered video analytics monitor crane activity in real time, tracking uptime, idle time, and occupancy through a centralized dashboard.

This optimizes crane and equipment usage, reduces operational costs, and provides data-driven insights for scheduling and resource planning.

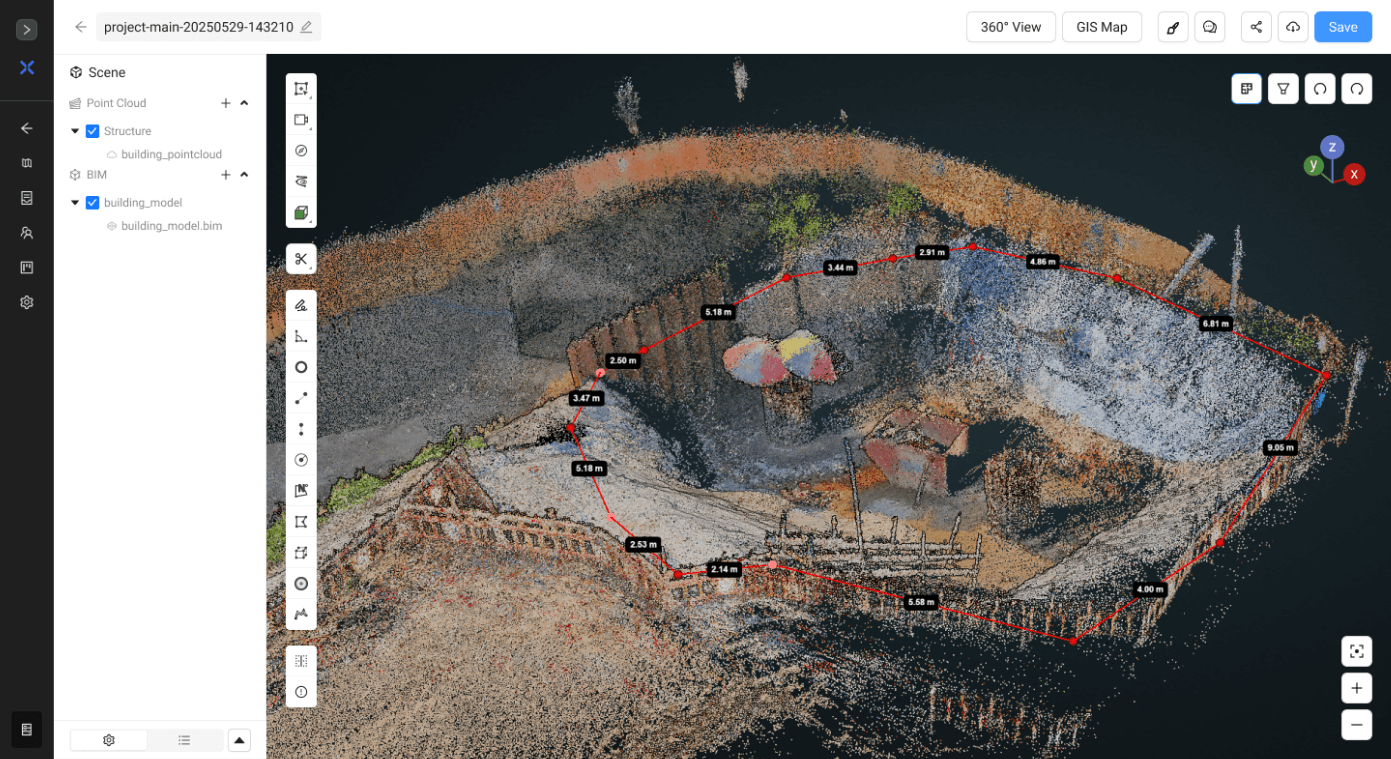

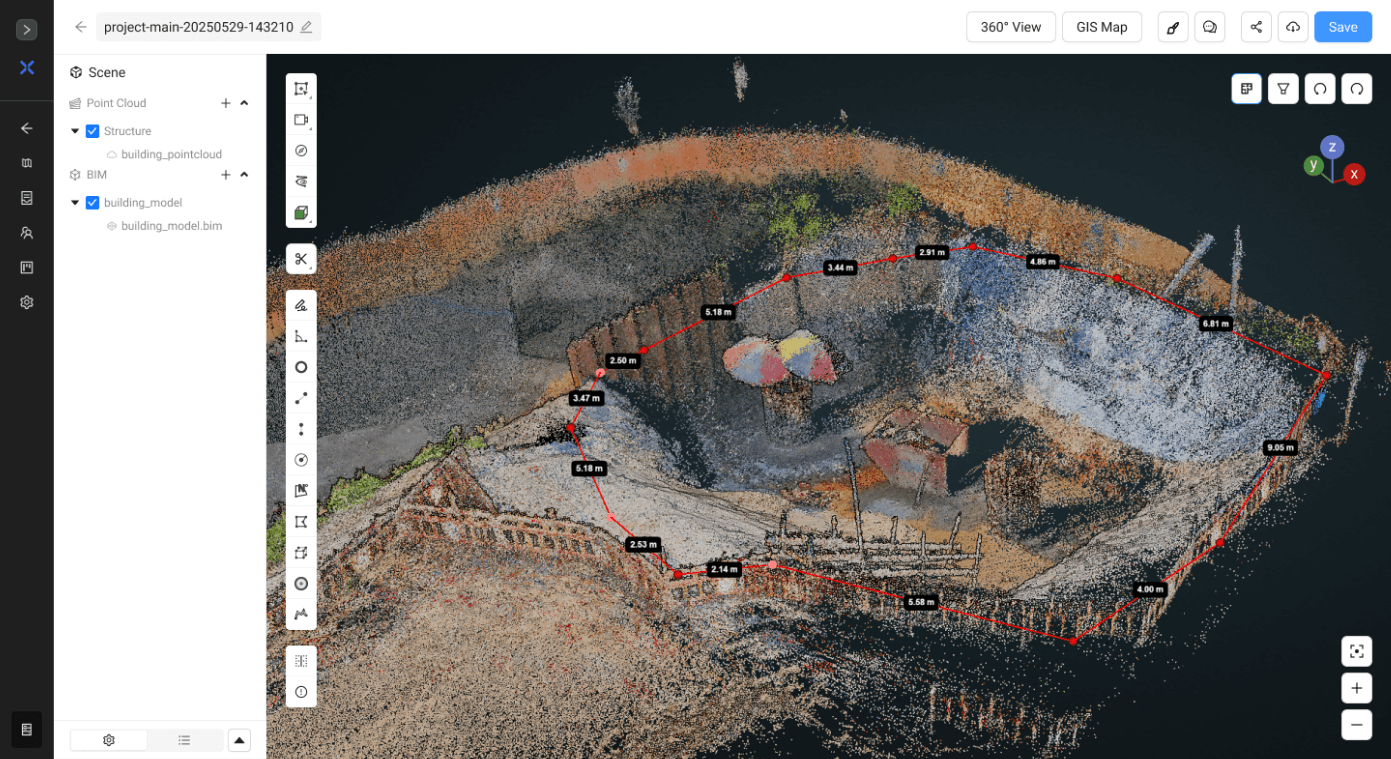

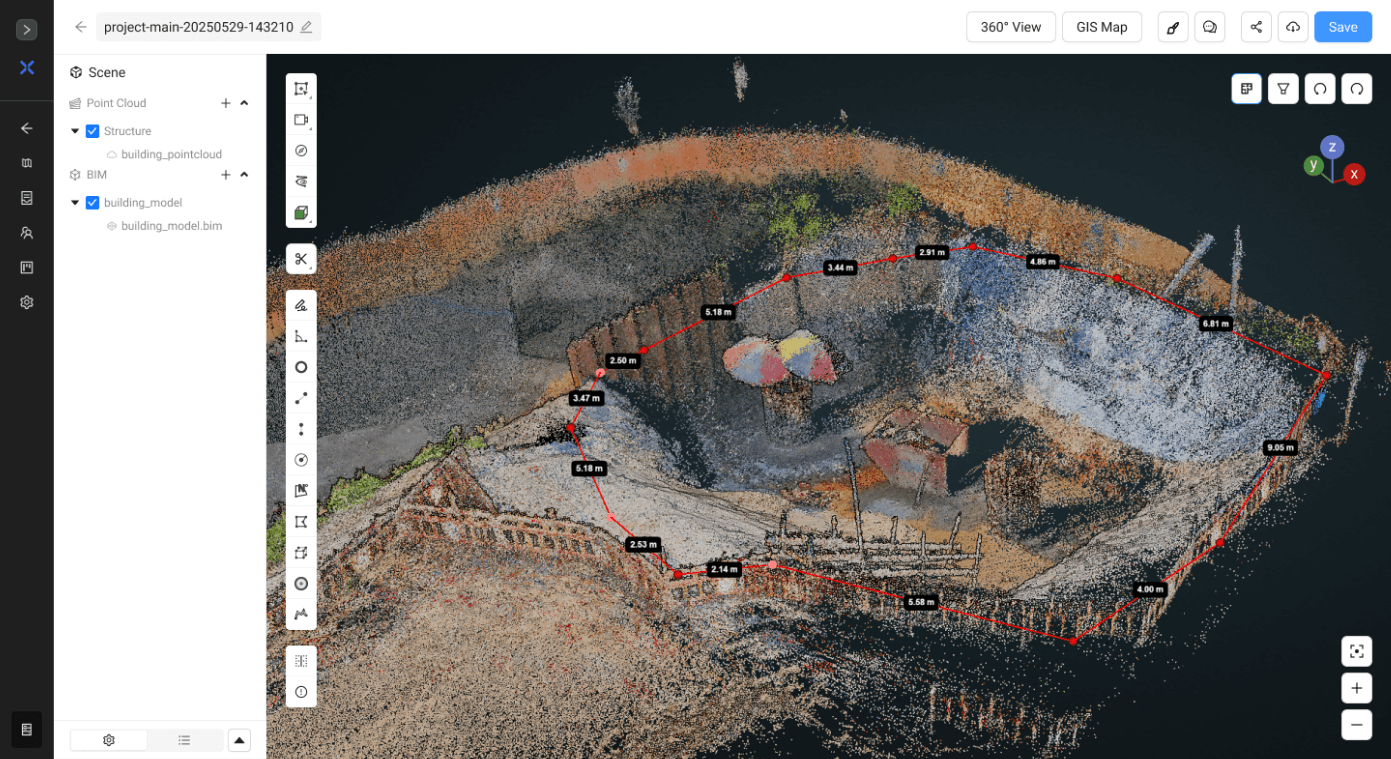

3. Slope Gradient Monitoring

Unstable slopes can lead to safety hazards, project delays, or regulatory non-compliance.

Using LiDAR equipped drone point clouds and digital terrain models (DTMs), SpatialSense tracks slope changes over time. These Instant remote inspections enable proactive detection of potential risks or inaccuracies.

Thisenhances site safety, supports compliance audits, and prevents costly slope-related delays and accidents.

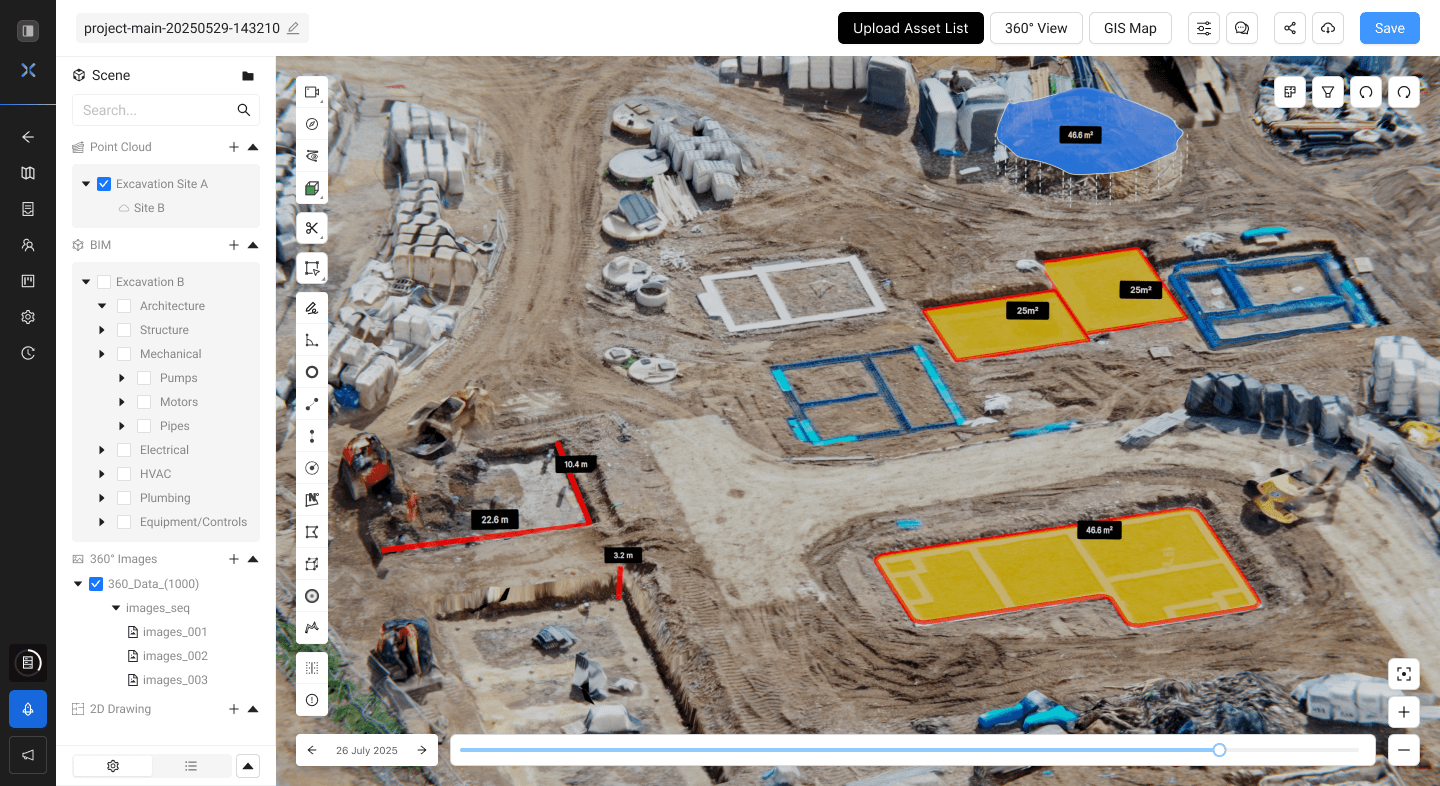

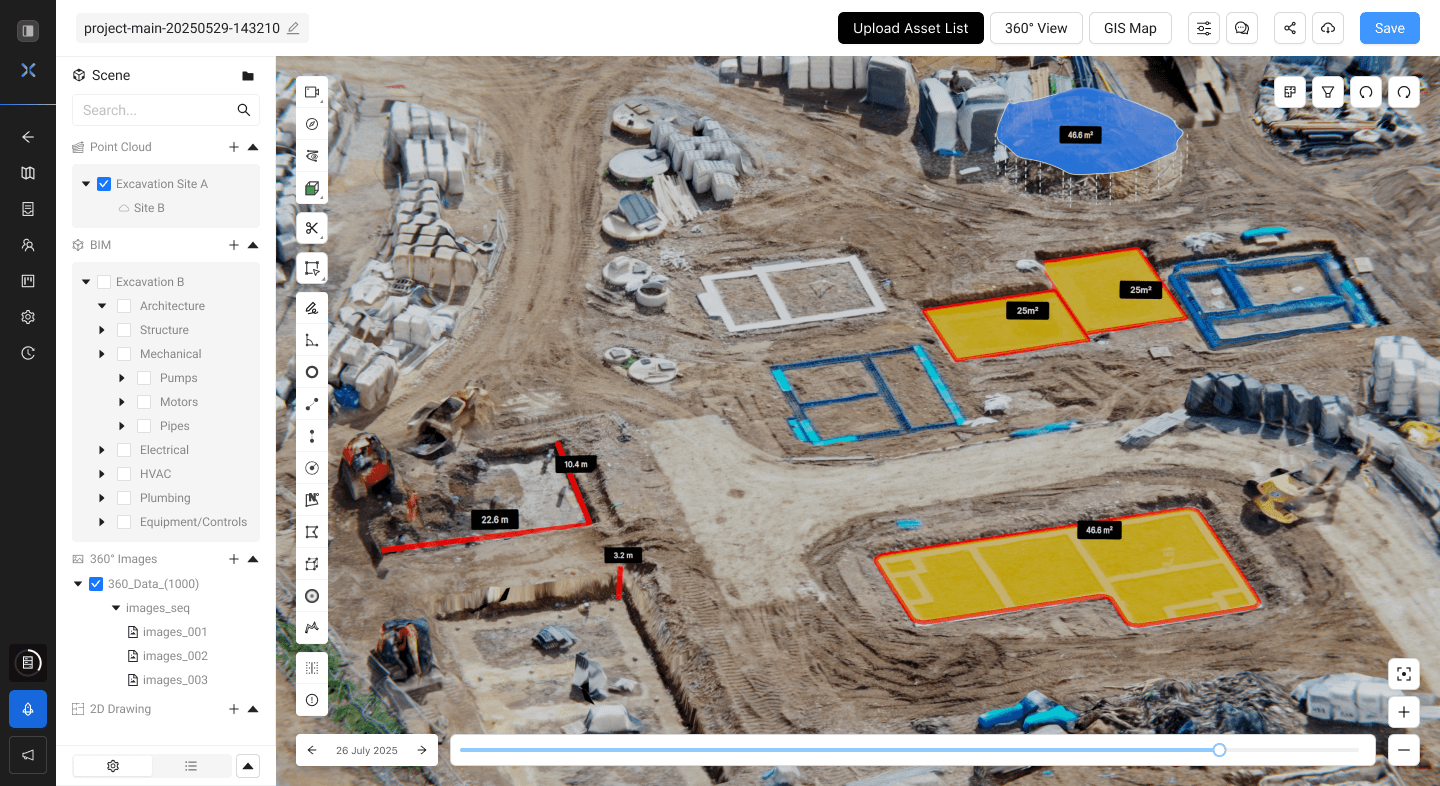

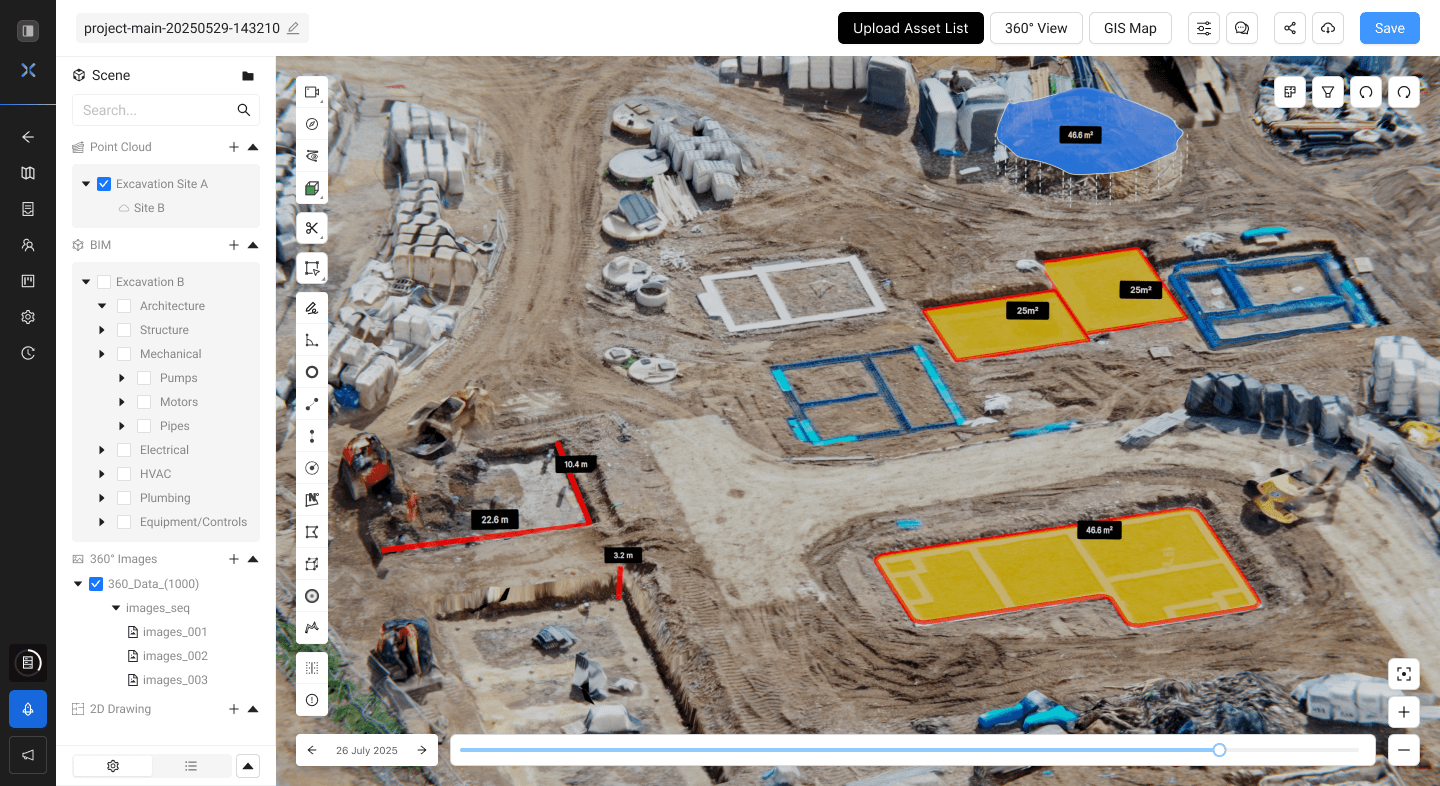

4. Excavation Monitoring

Excavation work requires precise cut-and-fill operations. Errors can lead to delays, disputes, or cost overruns.

Pairing hardware system like 4DRC’s fixed-point scanner & Spatial Scanner’s portability 4D Digital Twins can be generated which SpatialSense then utilizes to monitor and inspect excavation volumes. Cut/fill progress is tracked and compared with design plans.

This ensures accurate progress, prevents rework, and keeps projects on schedule and budget.

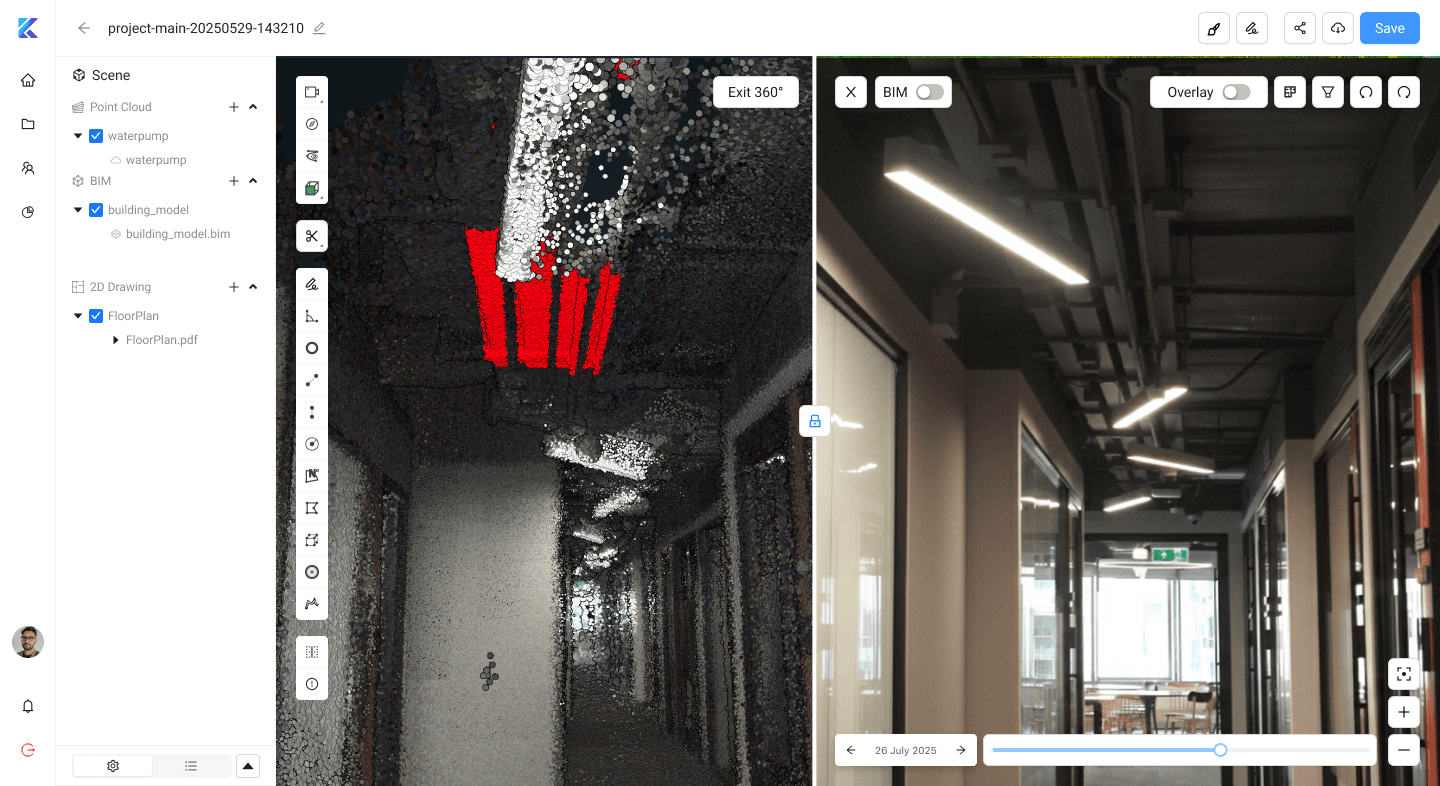

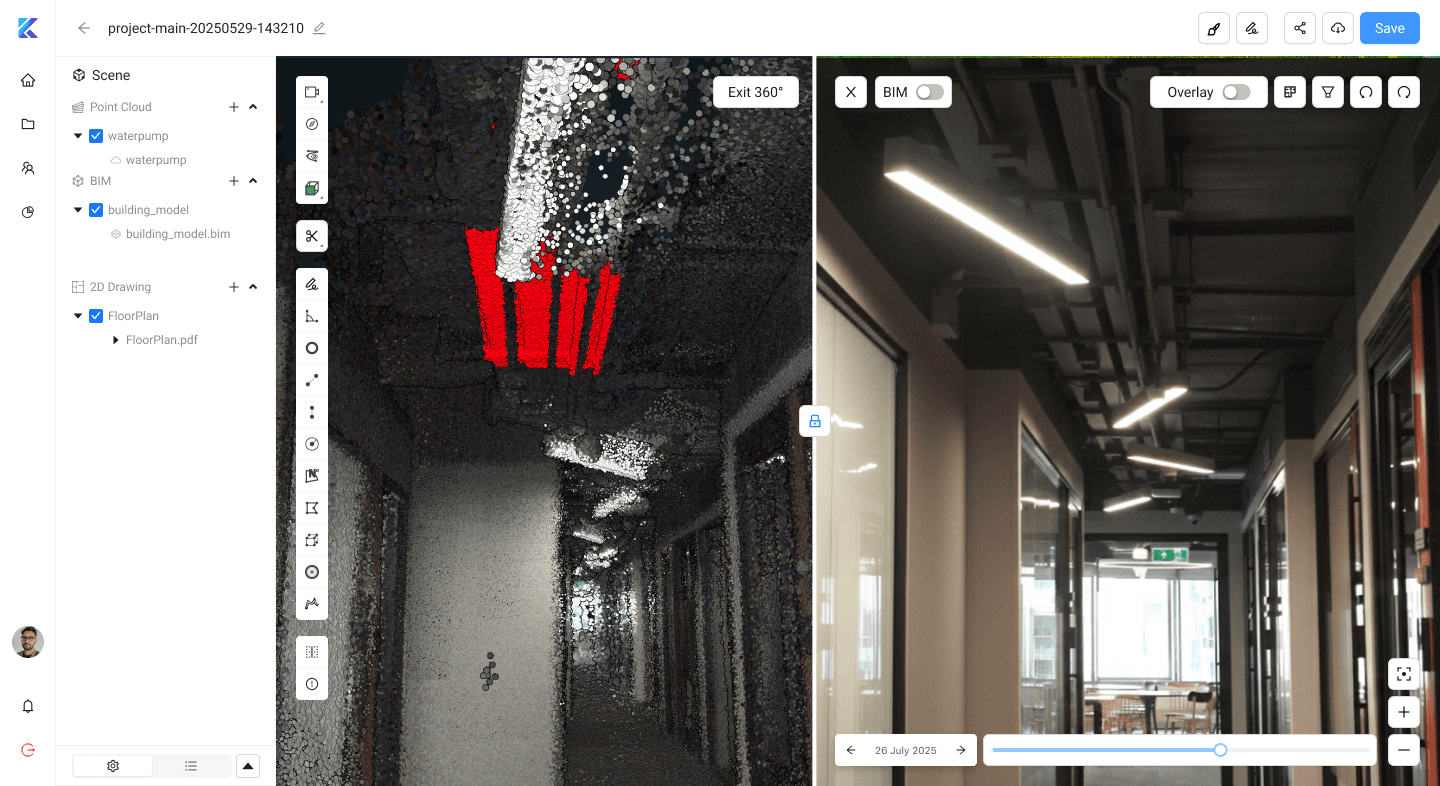

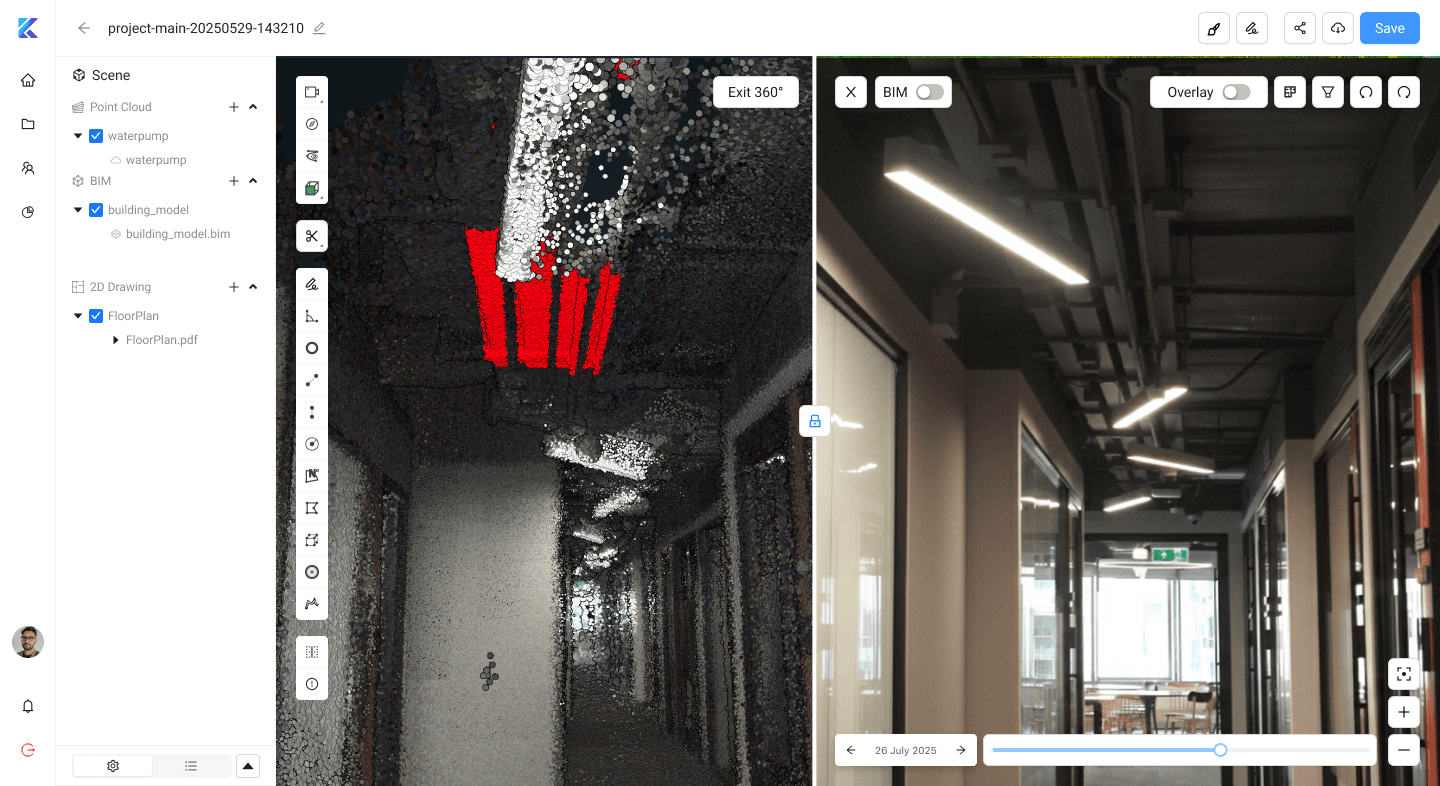

5. Building Facade & Furnishing Monitoring

Installing facades and interior furnishings involves multiple teams and materials. Mistakes can lead to quality issues and cost overruns.

Analyses digital twins combined with BIM comparison to validate installations. Each installed item is linked to the Bill of Materials (BOM) feature and budget tracking.

This improves quality assurance, prevents disputes, validates budget consumption, and ensures project completion aligns with design.

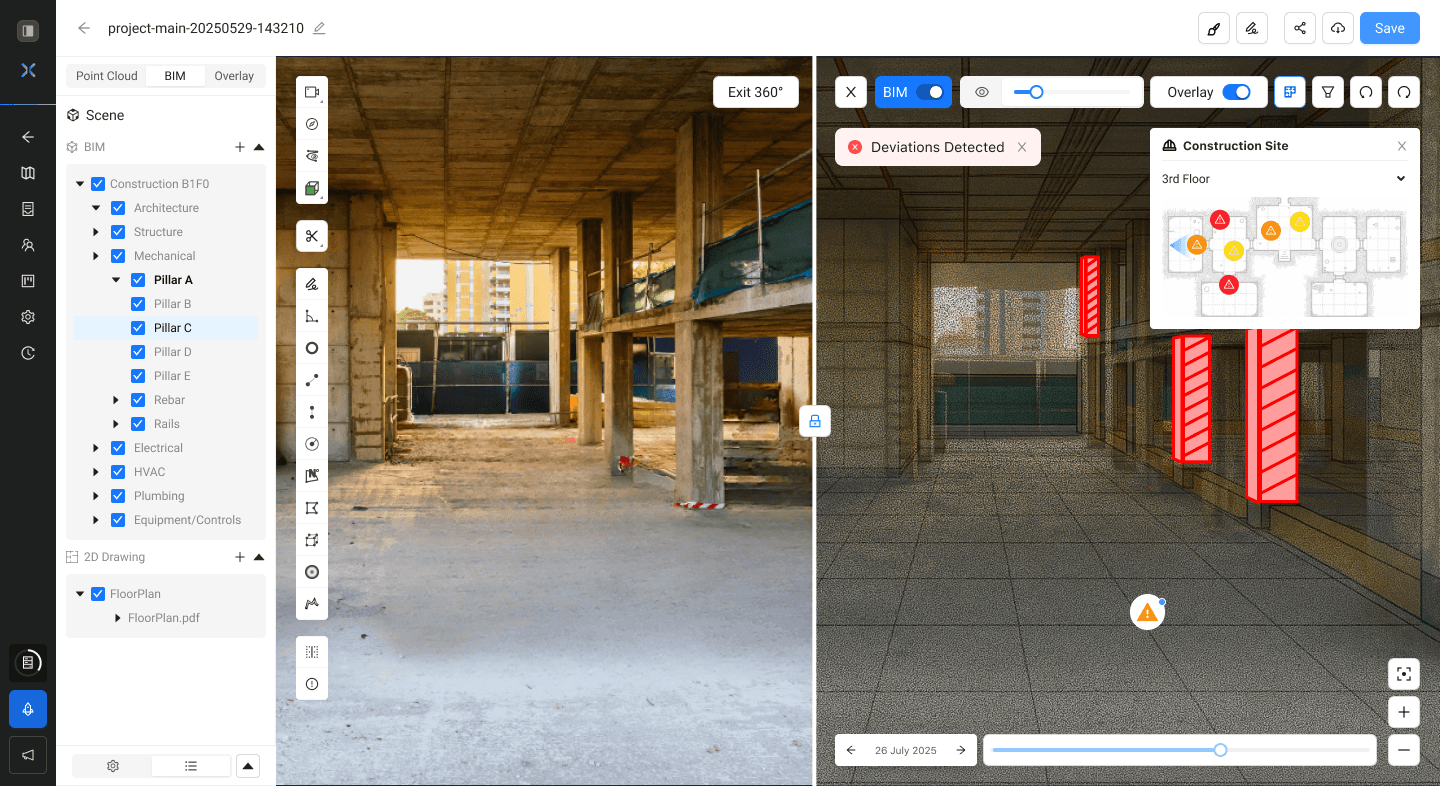

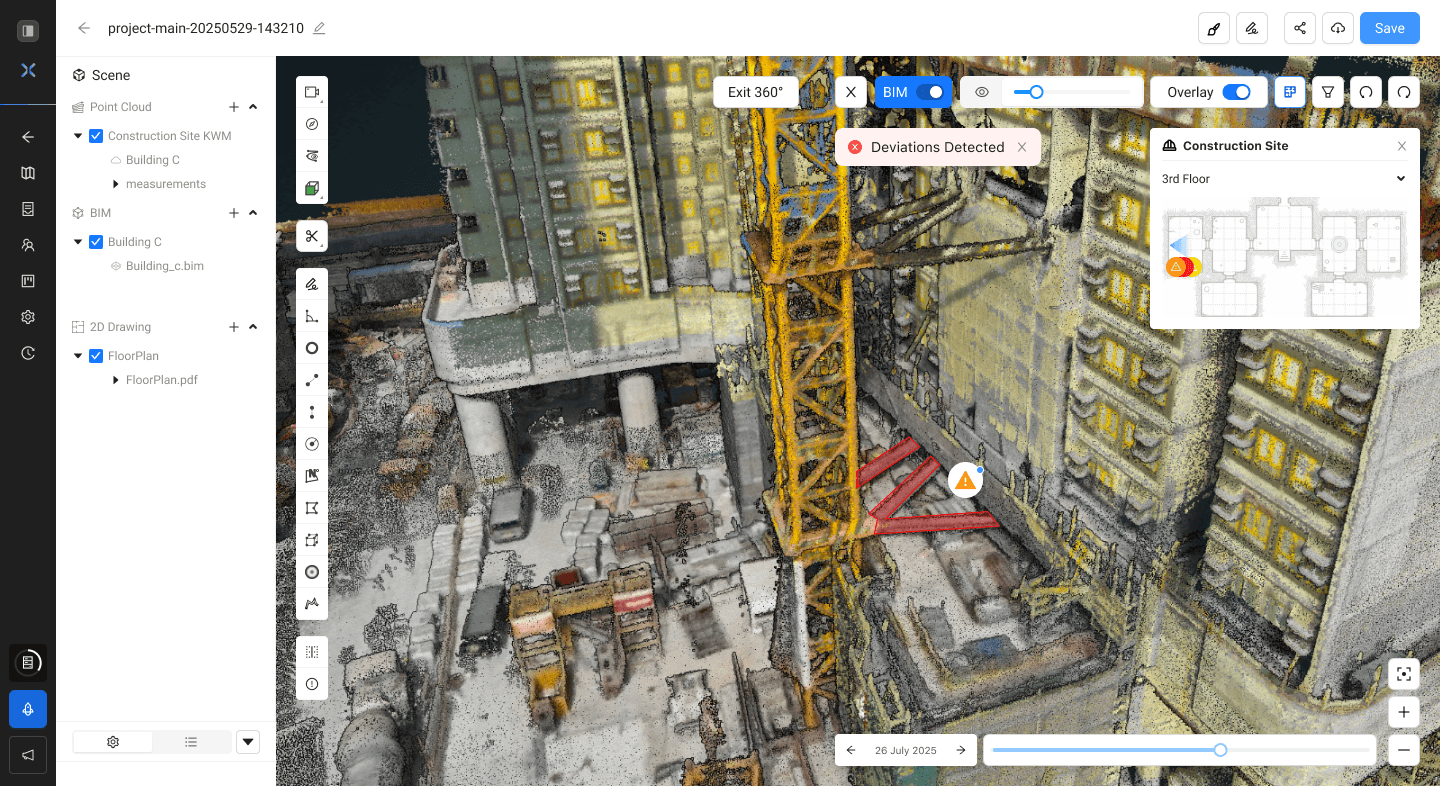

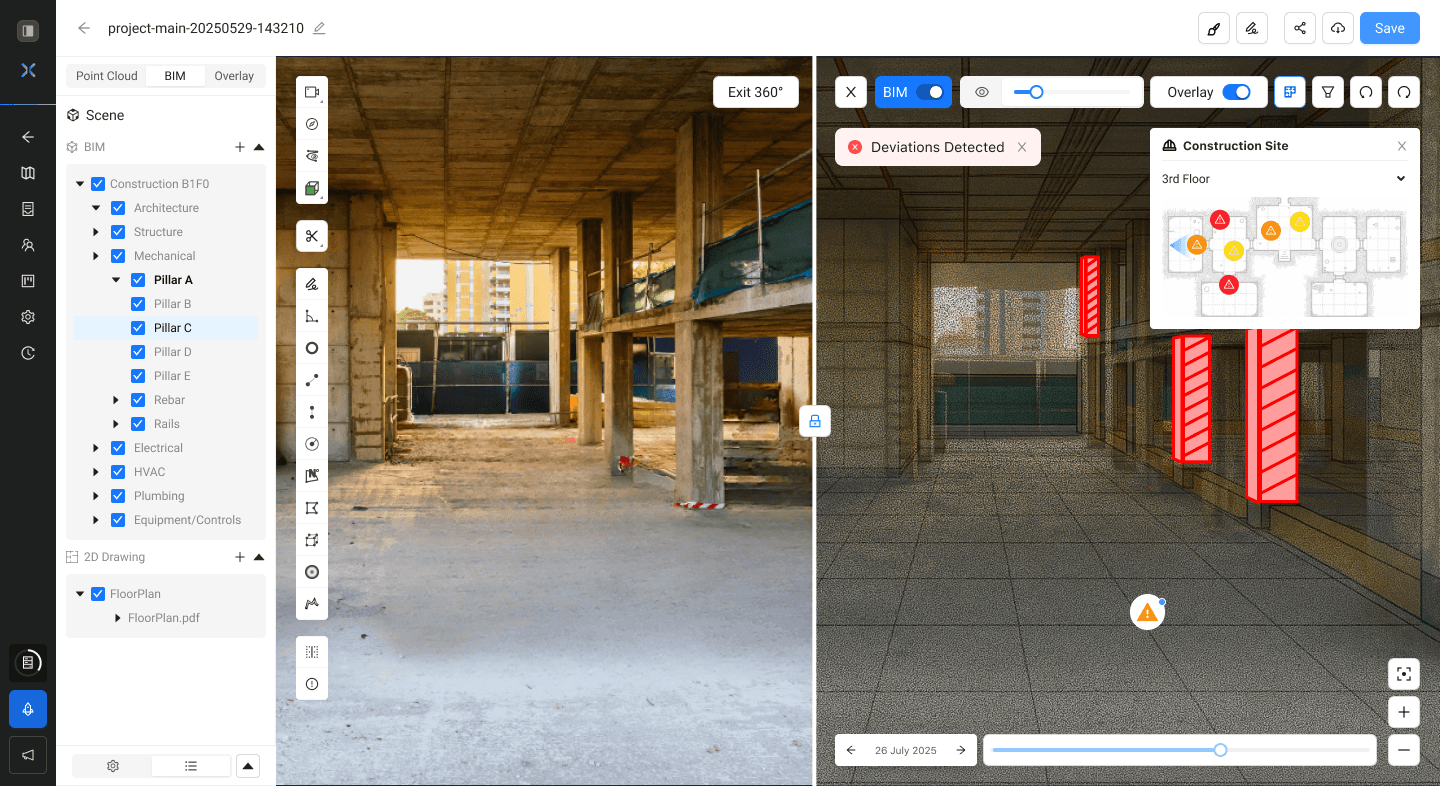

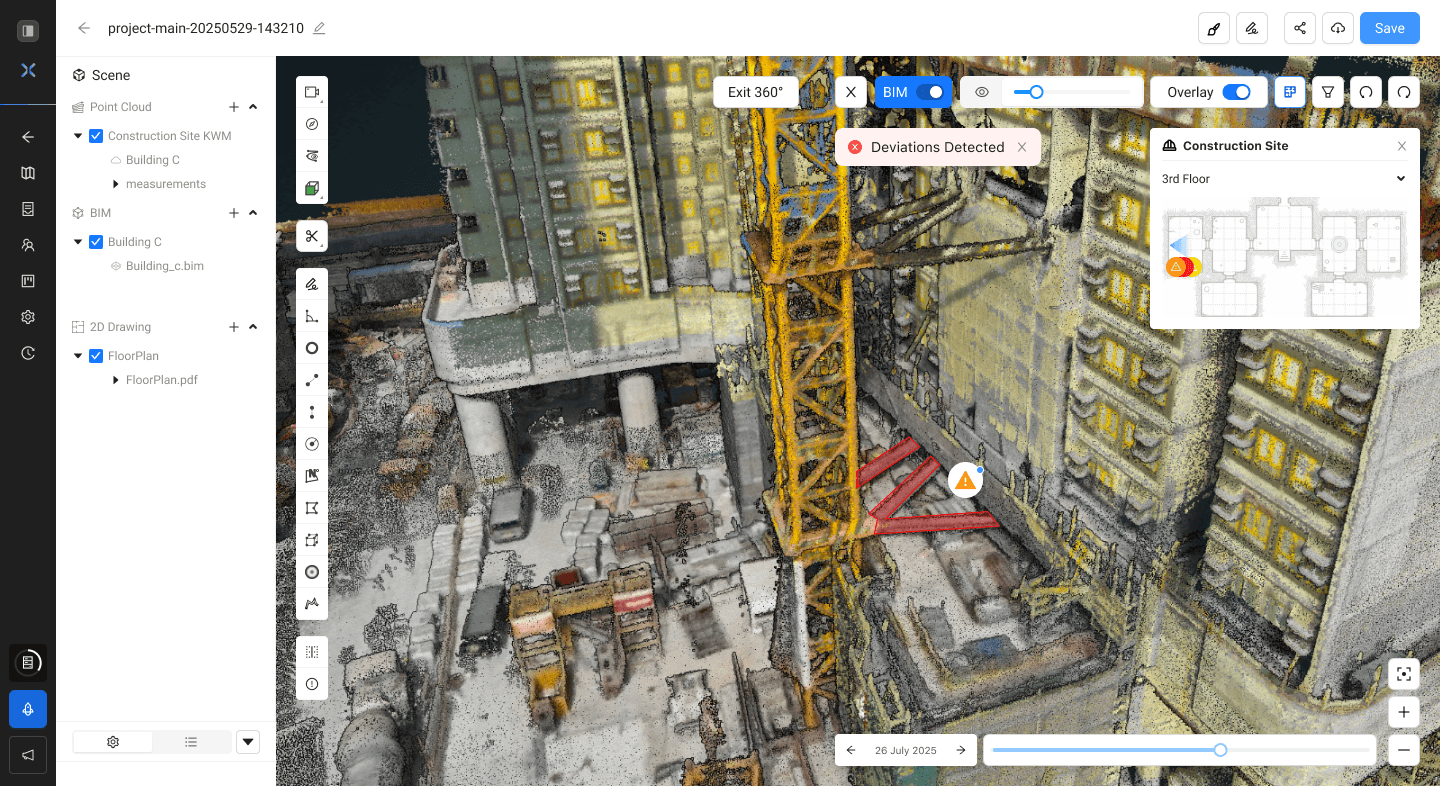

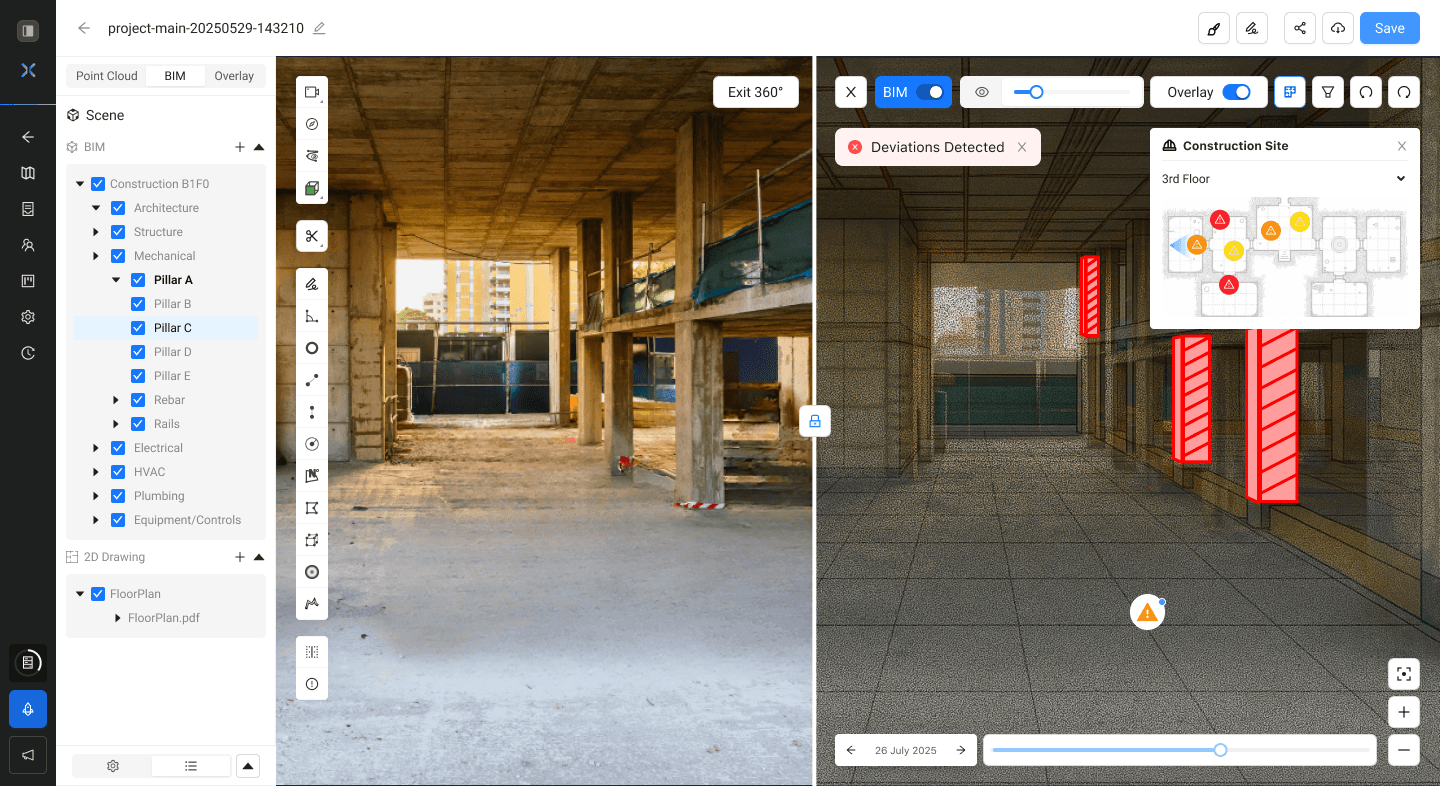

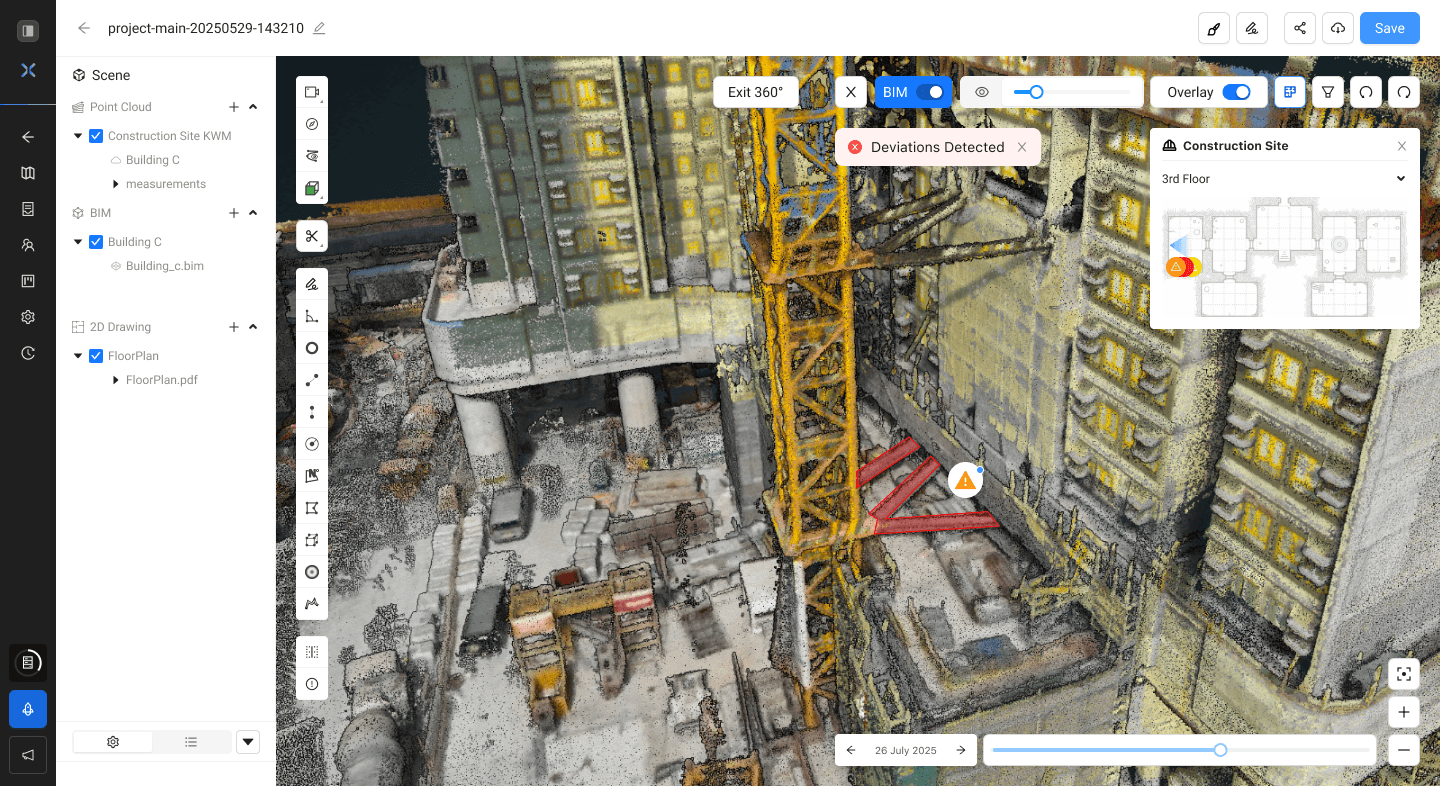

6. Deviation & Defect Detection

Misaligned walls, structural shifts, or surface defects often go unnoticed until rework costs escalate.

SpatialSense built-in tools automatically identify deviations, cracks, and surface defects, enabling early intervention with predictive foresight.

This saves time, resources, costs and ensures structural safety and compliance.

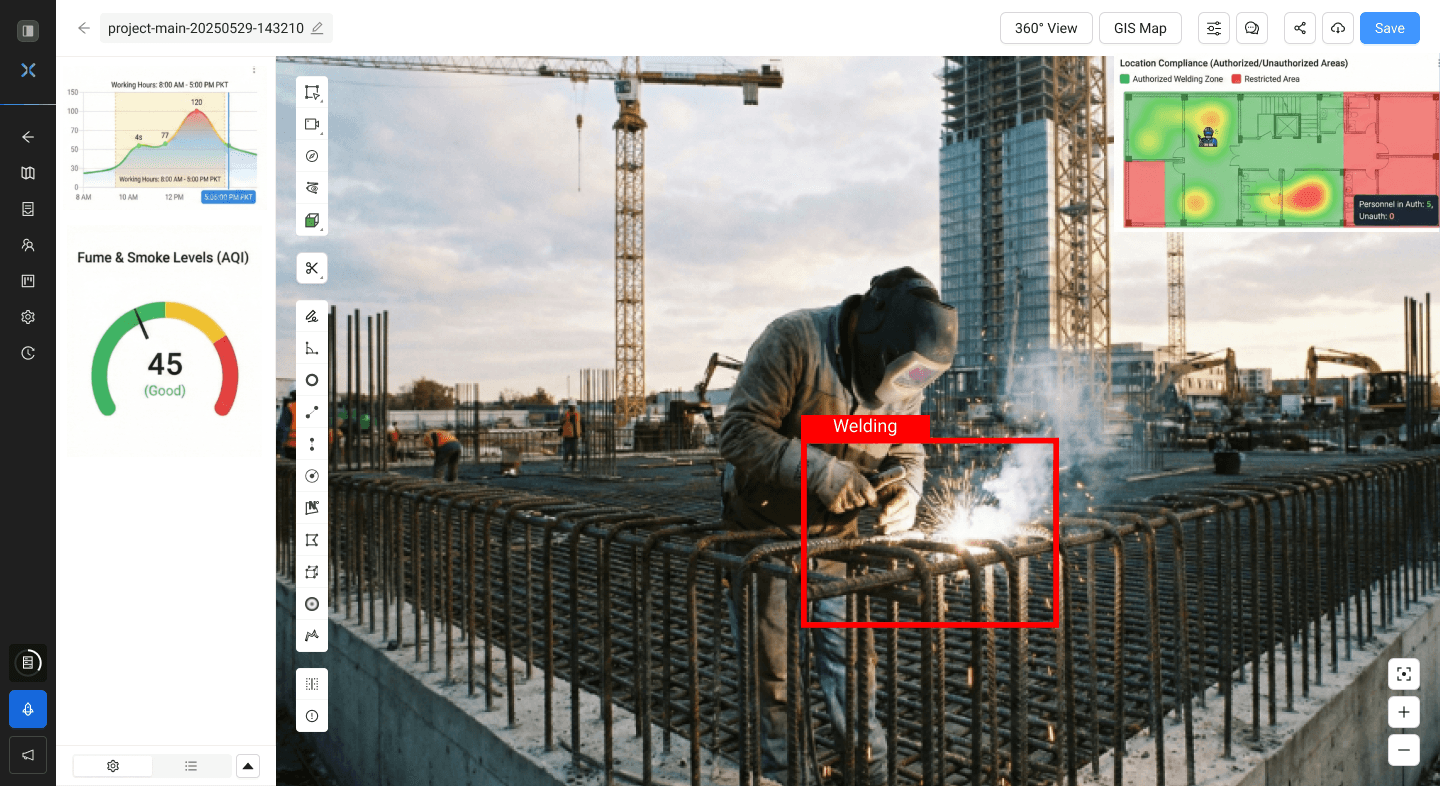

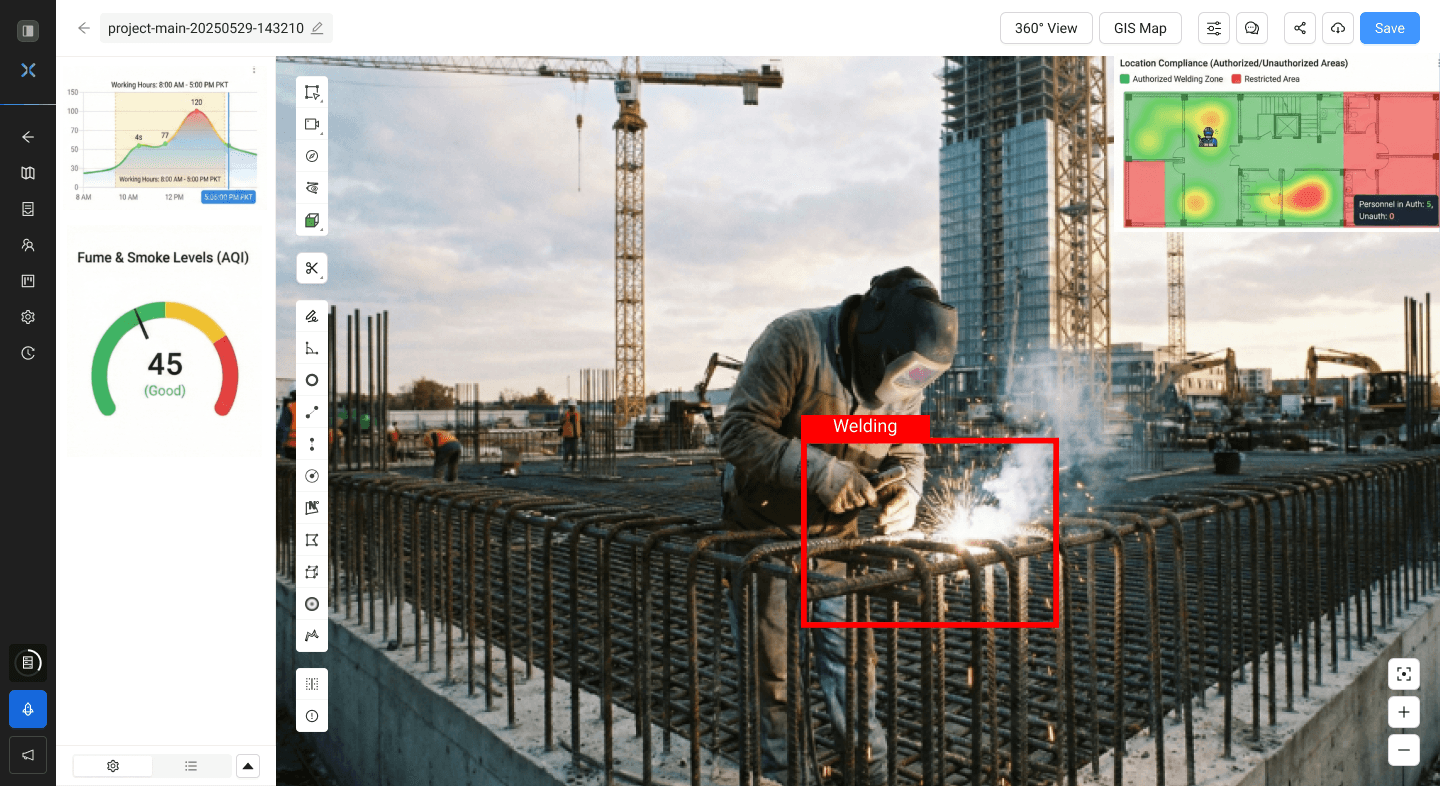

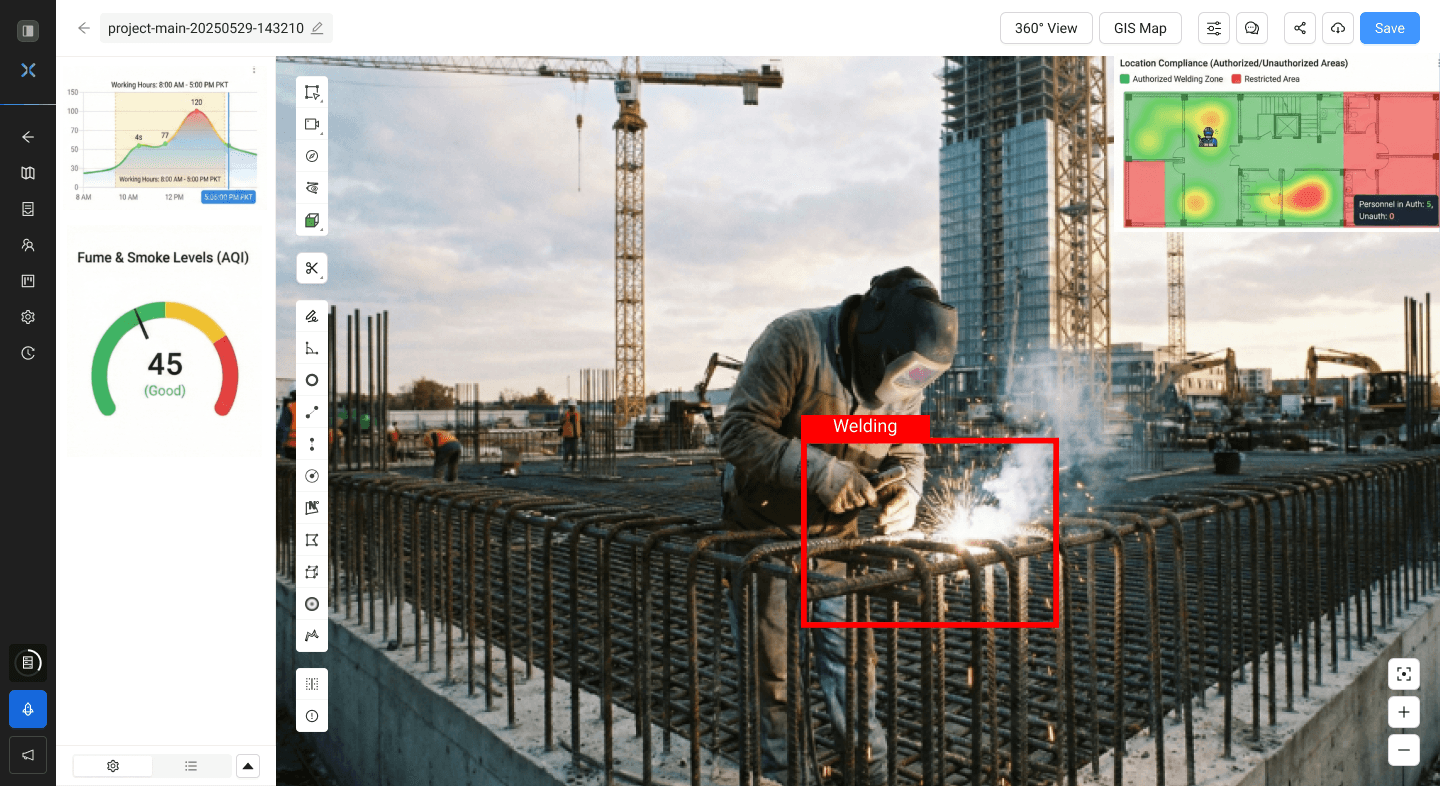

7. Worker Activity Tracking

Manual tracking of workforce presence, labour allocation, and restricted-area access is inefficient and error-prone.

AI-powered human activity tracking detects helmets, vests, and restricted-area intrusions. Real-time dashboards monitor labour distribution and shifts.

Another example is wielding activity monitoring where SpatialSense can detect all welding activities giving you insights like flagged hot-work outside authorized hours, logged events with timestamp & location for compliance, identification of fire, smoke, and unsafe intrusions giving you alerts to prevent safety incidents.

This enhances site safety, ensures accountability, and optimizes workforce deployment.

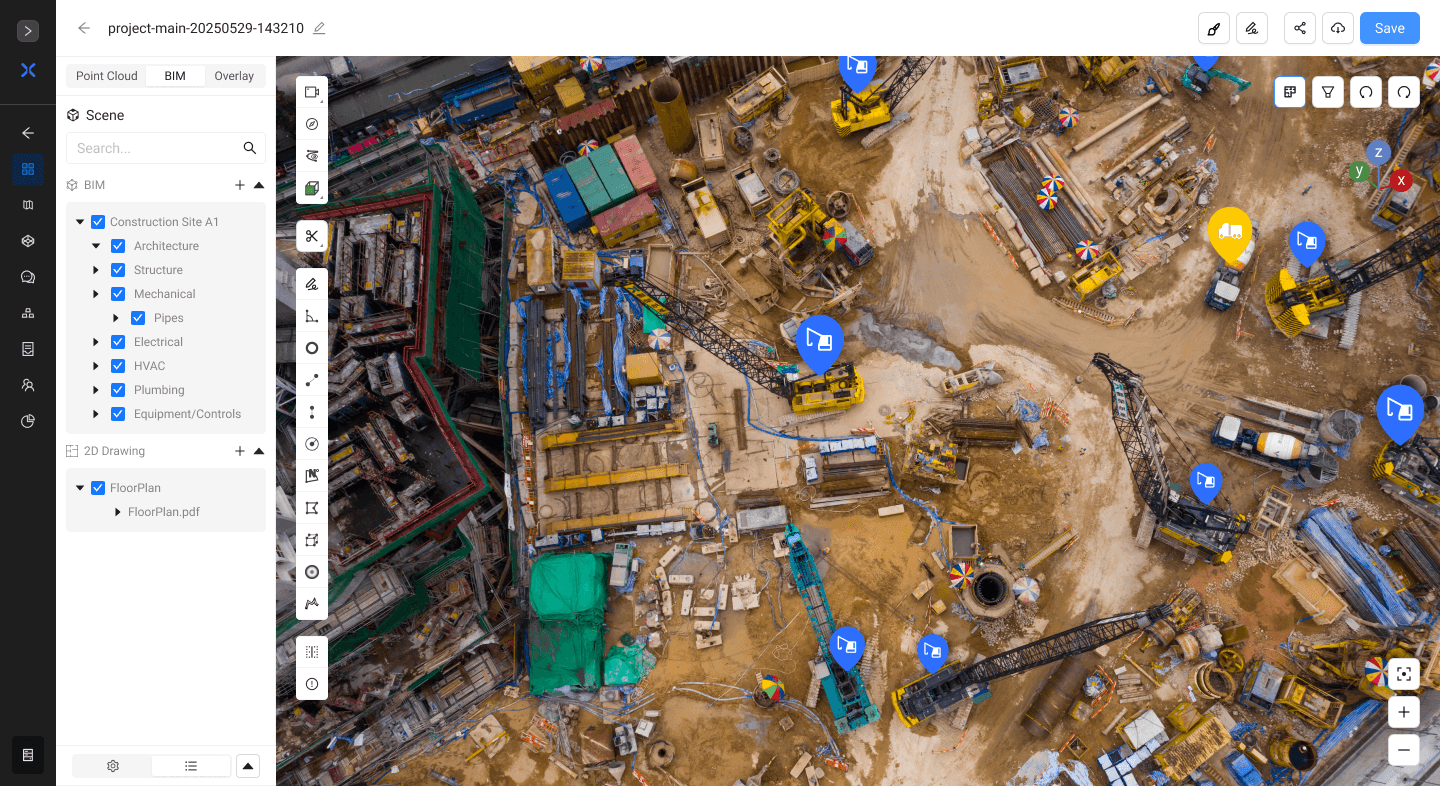

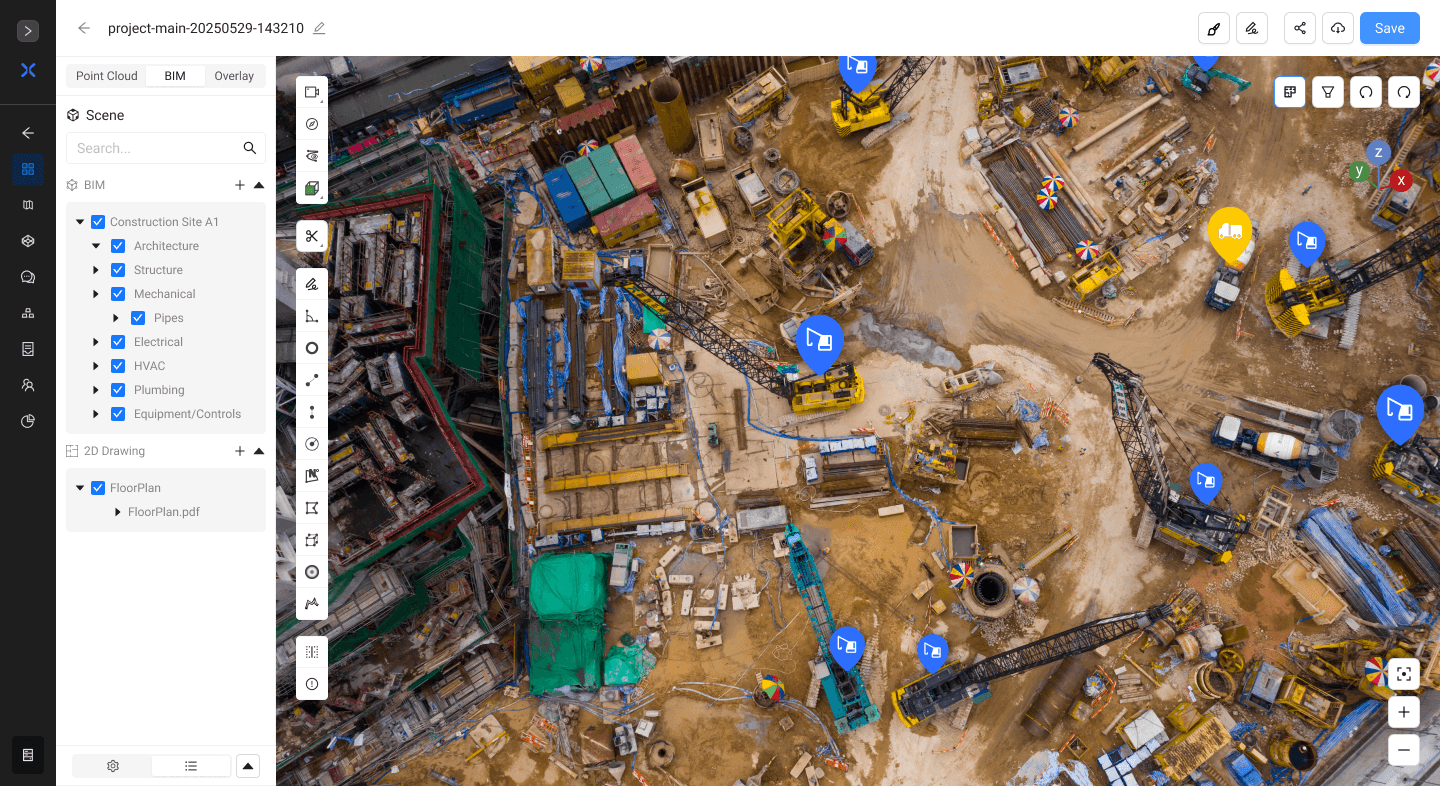

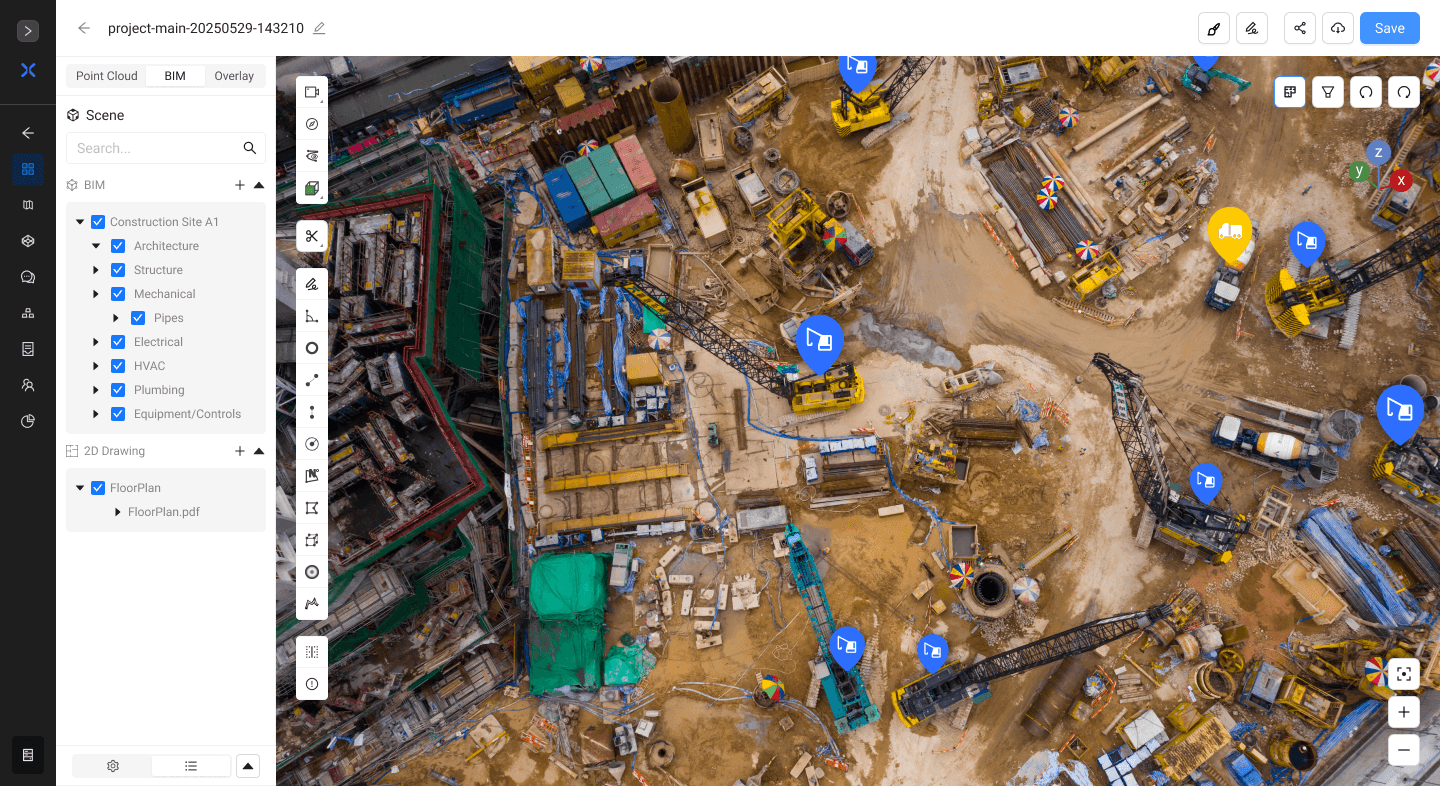

8. Equipment Tracking on-site

Construction sites struggle with lost, idle, or misallocated equipment, leading to delays and increased costs.

IoT sensors data utilized by SpatialSense provide real-time location and status of all equipment across the site. Dashboards consolidate data for easy monitoring.

Reduces losses, improves equipment utilization, and streamlines on-site operations.

9. Smart Rebar Progress Monitoring

Reinforcing bars (rebar) must be installed accurately according to structural drawings, mistakes can cause safety risks and delays.

SpatialSense inspects rebar installation stage-wise, highlighting completed, in-progress, and missing sections.

This reduces errors and rework, ensures QA/QC, and supports timely reporting and handovers.

10. Automated Safety Hazard Detection

Construction sites are prone to safety hazards that require immediate attention.

Detection of potential hazards likke unsafe scaffolding, open edges, or missing PPE (Personal Protective Equipment) and flagging them instantly on dashboards for rapid intervention.

This Minimizes accidents, enforces regulatory compliance, and enables proactive safety management.

Conclusion

Construction sites are complex, fast-moving, and expensive. Visibility at the operational level is no longer optional. SpatialSense turns real-world site activity into actionable data, helping teams deliver projects on time, on budget, and safely.

Explore how SpatialSense can be applied to your construction site and transform operational monitoring into a competitive advantage.

This blog highlights 10 key construction site operations, the challenges they encounter, and how a platform like SpatialSense can streamline, monitor, and optimize them.

1. Modular Integrated Construction (MiC) Progress Monitoring

Modular construction accelerates projects but can be difficult to manage due to complex logistics, limited visibility and having multiple stakeholders - leading to misaligned schedules or missing components.

A Platform like SpatialSense compares point-cloud captures with the BIM schedules (4D BIM), monitoring delivery, on-site assembly, and installation of modular components. AI detects completed, in-progress, and missing modules, while dashboards provide real-time progress percentages with various other analytics.

Enabling on-time, on-budget delivery, reduces dependency on manual reporting, and improves visibility for onsite activities.

2. Tower Crane & other Machinery Utilization

Tower cranes and other construction equipment are expensive and critical for operations, but traditional utilization is often tracked manually, causing inefficiencies and idle time.

SpatialSense’s AI-powered video analytics monitor crane activity in real time, tracking uptime, idle time, and occupancy through a centralized dashboard.

This optimizes crane and equipment usage, reduces operational costs, and provides data-driven insights for scheduling and resource planning.

3. Slope Gradient Monitoring

Unstable slopes can lead to safety hazards, project delays, or regulatory non-compliance.

Using LiDAR equipped drone point clouds and digital terrain models (DTMs), SpatialSense tracks slope changes over time. These Instant remote inspections enable proactive detection of potential risks or inaccuracies.

Thisenhances site safety, supports compliance audits, and prevents costly slope-related delays and accidents.

4. Excavation Monitoring

Excavation work requires precise cut-and-fill operations. Errors can lead to delays, disputes, or cost overruns.

Pairing hardware system like 4DRC’s fixed-point scanner & Spatial Scanner’s portability 4D Digital Twins can be generated which SpatialSense then utilizes to monitor and inspect excavation volumes. Cut/fill progress is tracked and compared with design plans.

This ensures accurate progress, prevents rework, and keeps projects on schedule and budget.

5. Building Facade & Furnishing Monitoring

Installing facades and interior furnishings involves multiple teams and materials. Mistakes can lead to quality issues and cost overruns.

Analyses digital twins combined with BIM comparison to validate installations. Each installed item is linked to the Bill of Materials (BOM) feature and budget tracking.

This improves quality assurance, prevents disputes, validates budget consumption, and ensures project completion aligns with design.

6. Deviation & Defect Detection

Misaligned walls, structural shifts, or surface defects often go unnoticed until rework costs escalate.

SpatialSense built-in tools automatically identify deviations, cracks, and surface defects, enabling early intervention with predictive foresight.

This saves time, resources, costs and ensures structural safety and compliance.

7. Worker Activity Tracking

Manual tracking of workforce presence, labour allocation, and restricted-area access is inefficient and error-prone.

AI-powered human activity tracking detects helmets, vests, and restricted-area intrusions. Real-time dashboards monitor labour distribution and shifts.

Another example is wielding activity monitoring where SpatialSense can detect all welding activities giving you insights like flagged hot-work outside authorized hours, logged events with timestamp & location for compliance, identification of fire, smoke, and unsafe intrusions giving you alerts to prevent safety incidents.

This enhances site safety, ensures accountability, and optimizes workforce deployment.

8. Equipment Tracking on-site

Construction sites struggle with lost, idle, or misallocated equipment, leading to delays and increased costs.

IoT sensors data utilized by SpatialSense provide real-time location and status of all equipment across the site. Dashboards consolidate data for easy monitoring.

Reduces losses, improves equipment utilization, and streamlines on-site operations.

9. Smart Rebar Progress Monitoring

Reinforcing bars (rebar) must be installed accurately according to structural drawings, mistakes can cause safety risks and delays.

SpatialSense inspects rebar installation stage-wise, highlighting completed, in-progress, and missing sections.

This reduces errors and rework, ensures QA/QC, and supports timely reporting and handovers.

10. Automated Safety Hazard Detection

Construction sites are prone to safety hazards that require immediate attention.

Detection of potential hazards likke unsafe scaffolding, open edges, or missing PPE (Personal Protective Equipment) and flagging them instantly on dashboards for rapid intervention.

This Minimizes accidents, enforces regulatory compliance, and enables proactive safety management.

Conclusion

Construction sites are complex, fast-moving, and expensive. Visibility at the operational level is no longer optional. SpatialSense turns real-world site activity into actionable data, helping teams deliver projects on time, on budget, and safely.

Explore how SpatialSense can be applied to your construction site and transform operational monitoring into a competitive advantage.

This blog highlights 10 key construction site operations, the challenges they encounter, and how a platform like SpatialSense can streamline, monitor, and optimize them.

1. Modular Integrated Construction (MiC) Progress Monitoring

Modular construction accelerates projects but can be difficult to manage due to complex logistics, limited visibility and having multiple stakeholders - leading to misaligned schedules or missing components.

A Platform like SpatialSense compares point-cloud captures with the BIM schedules (4D BIM), monitoring delivery, on-site assembly, and installation of modular components. AI detects completed, in-progress, and missing modules, while dashboards provide real-time progress percentages with various other analytics.

Enabling on-time, on-budget delivery, reduces dependency on manual reporting, and improves visibility for onsite activities.

2. Tower Crane & other Machinery Utilization

Tower cranes and other construction equipment are expensive and critical for operations, but traditional utilization is often tracked manually, causing inefficiencies and idle time.

SpatialSense’s AI-powered video analytics monitor crane activity in real time, tracking uptime, idle time, and occupancy through a centralized dashboard.

This optimizes crane and equipment usage, reduces operational costs, and provides data-driven insights for scheduling and resource planning.

3. Slope Gradient Monitoring

Unstable slopes can lead to safety hazards, project delays, or regulatory non-compliance.

Using LiDAR equipped drone point clouds and digital terrain models (DTMs), SpatialSense tracks slope changes over time. These Instant remote inspections enable proactive detection of potential risks or inaccuracies.

Thisenhances site safety, supports compliance audits, and prevents costly slope-related delays and accidents.

4. Excavation Monitoring

Excavation work requires precise cut-and-fill operations. Errors can lead to delays, disputes, or cost overruns.

Pairing hardware system like 4DRC’s fixed-point scanner & Spatial Scanner’s portability 4D Digital Twins can be generated which SpatialSense then utilizes to monitor and inspect excavation volumes. Cut/fill progress is tracked and compared with design plans.

This ensures accurate progress, prevents rework, and keeps projects on schedule and budget.

5. Building Facade & Furnishing Monitoring

Installing facades and interior furnishings involves multiple teams and materials. Mistakes can lead to quality issues and cost overruns.

Analyses digital twins combined with BIM comparison to validate installations. Each installed item is linked to the Bill of Materials (BOM) feature and budget tracking.

This improves quality assurance, prevents disputes, validates budget consumption, and ensures project completion aligns with design.

6. Deviation & Defect Detection

Misaligned walls, structural shifts, or surface defects often go unnoticed until rework costs escalate.

SpatialSense built-in tools automatically identify deviations, cracks, and surface defects, enabling early intervention with predictive foresight.

This saves time, resources, costs and ensures structural safety and compliance.

7. Worker Activity Tracking

Manual tracking of workforce presence, labour allocation, and restricted-area access is inefficient and error-prone.

AI-powered human activity tracking detects helmets, vests, and restricted-area intrusions. Real-time dashboards monitor labour distribution and shifts.

Another example is wielding activity monitoring where SpatialSense can detect all welding activities giving you insights like flagged hot-work outside authorized hours, logged events with timestamp & location for compliance, identification of fire, smoke, and unsafe intrusions giving you alerts to prevent safety incidents.

This enhances site safety, ensures accountability, and optimizes workforce deployment.

8. Equipment Tracking on-site

Construction sites struggle with lost, idle, or misallocated equipment, leading to delays and increased costs.

IoT sensors data utilized by SpatialSense provide real-time location and status of all equipment across the site. Dashboards consolidate data for easy monitoring.

Reduces losses, improves equipment utilization, and streamlines on-site operations.

9. Smart Rebar Progress Monitoring

Reinforcing bars (rebar) must be installed accurately according to structural drawings, mistakes can cause safety risks and delays.

SpatialSense inspects rebar installation stage-wise, highlighting completed, in-progress, and missing sections.

This reduces errors and rework, ensures QA/QC, and supports timely reporting and handovers.

10. Automated Safety Hazard Detection

Construction sites are prone to safety hazards that require immediate attention.

Detection of potential hazards likke unsafe scaffolding, open edges, or missing PPE (Personal Protective Equipment) and flagging them instantly on dashboards for rapid intervention.

This Minimizes accidents, enforces regulatory compliance, and enables proactive safety management.

Conclusion

Construction sites are complex, fast-moving, and expensive. Visibility at the operational level is no longer optional. SpatialSense turns real-world site activity into actionable data, helping teams deliver projects on time, on budget, and safely.

Explore how SpatialSense can be applied to your construction site and transform operational monitoring into a competitive advantage.

Table of Content

Jan 29, 2026

Interested to find out how Kodifly transforms the infrastructure space?

10 Construction Site Operations Powered by SpatialSense

Jan 29, 2026

Who Can Benefit from SpatialSense and How?

Dec 30, 2025

Smarter O&M with Temperature Data & Digital Twins

Nov 28, 2025

Building Durable Roads with Kodifly’s Research-Backed Asset Monitoring

Nov 11, 2025